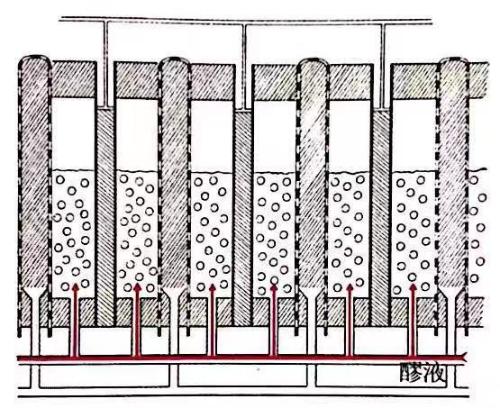

(1) Mash Entry: The mash is pumped into “membrane filter tank” from both sides of bottom through lower channel at a pressure of 15-20 kPa, and first wort flows out of filter cloth. strainer plates immediately.

Pour into puree

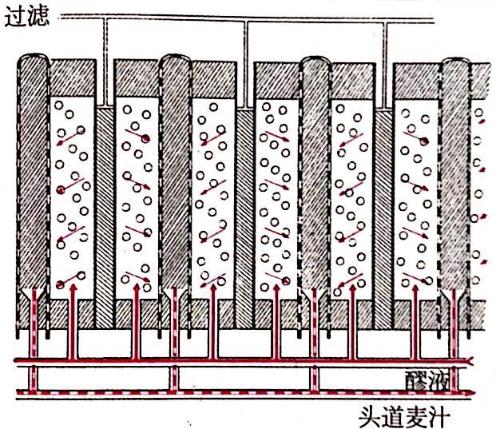

(2) Filtration: As mash is continuously fed, layer of wheat grains in filter frame becomes thicker and thicker, and first wort also continuously flows out. After all mash is pumped into filter press, all chambers of filter frame are filled with grain, and first wort filtration takes about 20 minutes.

Filtration of first wort

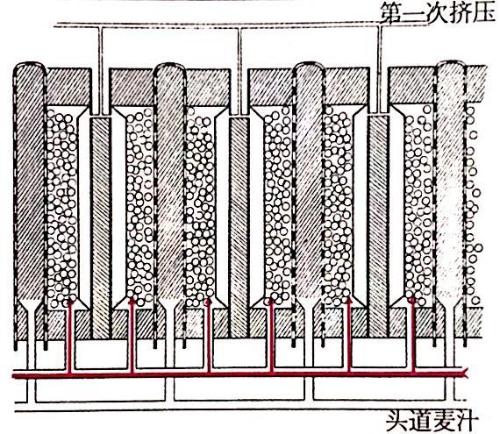

(3) First compression: compress wheat trough after all first wort is filtered out, and use 50-60kPa compressed air to press membrane on membrane frame plate against wheat trough to squeeze out wheat trough. first wort in trough. This process takes about 5 minutes.

First shrink

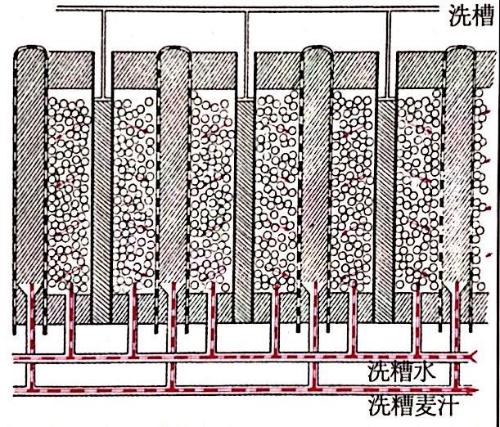

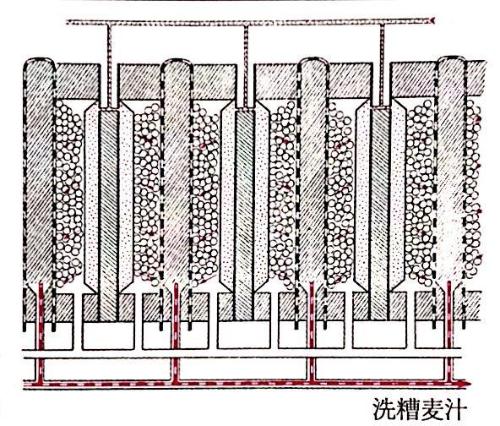

(4) Grain washing: washing water is pumped into filter press from below as a mash, and evenly distributed over filter bed, 78C washing water passes through wheat grain layer to wash out residual extracts, washing bad wort flows out through grate through filter cloth . This process takes most time and takes 50-55 minutes.

Sink

(5) Final compression: Press wheat trough again at end of filtration, and pressure will rise to 70 kPa to squeeze out residual extract from wheat trough and at same time moisture in trough. The wheat trough drops to about 32%, which is easy to transport. The wheat trough can also be compressed with a pressure above 120 kPa, so that water content will be lower, but if wheat trough is too dry, pipe will be blocked, which is inconvenient for a quick sale. This process takes about 10 minutes.

Full compression

(6) Drainage: Turn on filter press, and wheat trough falls into wheat waste tank, where residual wheat waste needs to be checked. This process takes about 10 minutes. After dumping waste, filter press is assembled again to filter sugared mash. The filter cloth can be washed immediately without removing it during cleaning. The disassembly and assembly of filter press can be carried out automatically, which reduces labor intensity and simplifies operation.

The total working time of filter press is 100~110 minutes at a time, and interval between making two vats of wort can be reduced to 2 hours, which means that 12 cups of wort can be produced every day.

(7) Cleaning: after saccharification is completed, every week filter cloth should be washed, when cleaning, filter cloth does not need to be removed (straw grains and sticky particles) are also washed off, and then filter press is thoroughly washed with water.

(8) Operation at beginning of weekly saccharification: filter press must be preheated before starting a new saccharification cycle, and a weak acid solution must be used to neutralize. Pay attention to external temperature of filter press. at end of weekly saccharification, it should be below body temperature, and fuselage should not be hot when touched by hands.

Craft beer process---filter press filter process in brewery

craft beer brewing process

The process of making craft beer

Craft beer brewing process - saccharification, boiling

What do you know about craft beer saccharification process?

Beer brewing - process

What is production process, raw materials and market for French beer?

Hygienic requirements for production process of equipment for home brewing beer

Craft beer - German craft beer

Why is there so much emphasis on hops in craft beer?